Industrialize Your Procurement Organization

Industrializing Procurement

Introducing a Smart Procurement Organization

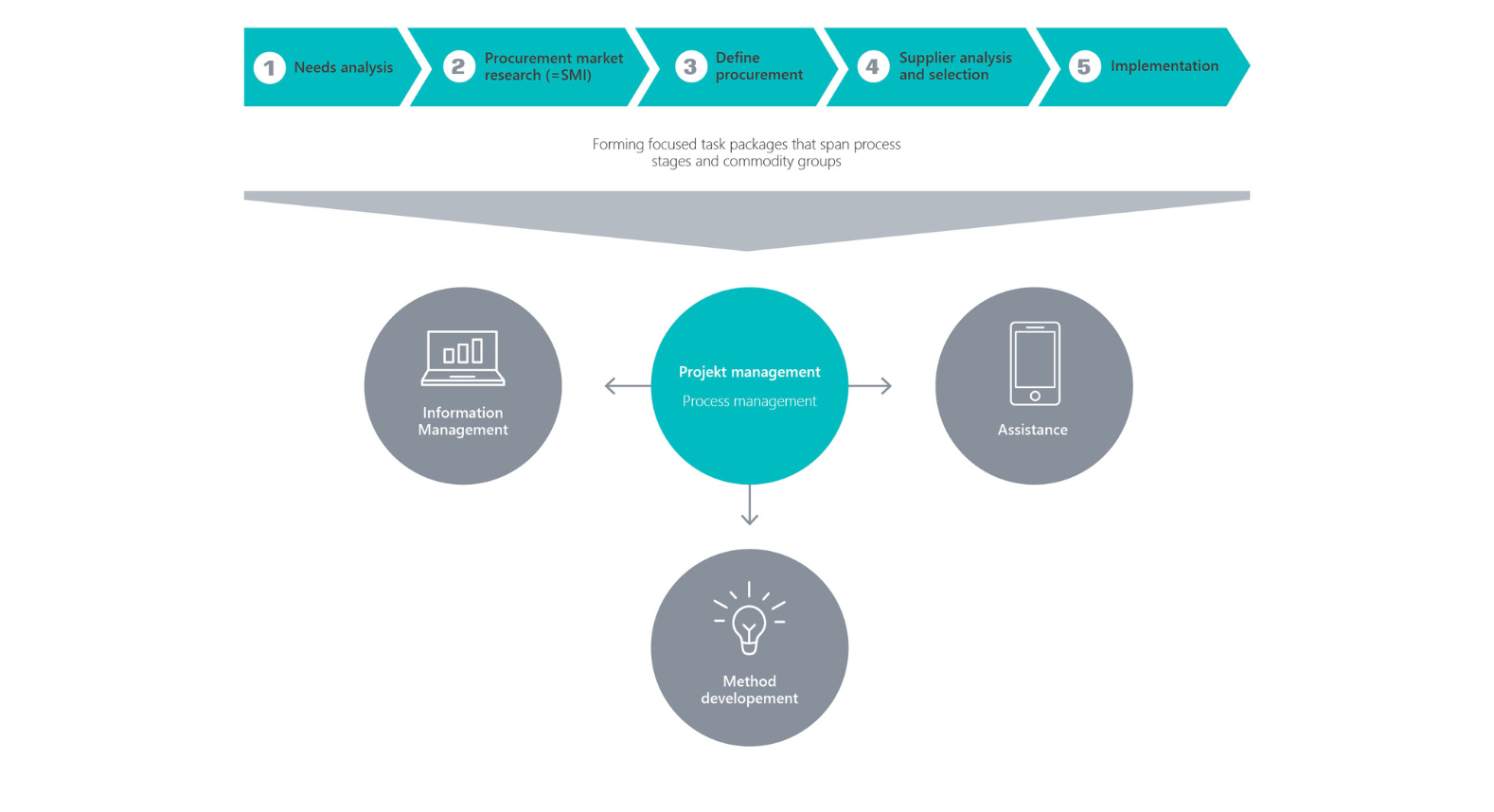

Industrialization is the second horizon of the IDEa concept. A smart procurement organization is established in order to optimize core processes. Focused task packages are put together across the strategic procurement process to industrialize and standardize procurement.

Procurement has evolved significantly over the last 20 years as a result of technological, methodological, and process-related changes such as strategic sourcing and eProcurement. But although procurement’s role has become more important in a world full of complex value chains, many businesses’ procurement organizationshave barely changed since the lead buyer model was introduced.

Discussions around organizational issues in procurement tend to focus on how much centralization is needed to meet the requirements of standardization and volume bundling on the one hand, and proximity to procurement markets and customers on the other. But achieving top performance in Procurement 4.0 involves pulling other organizational levers too. This article explores how procurement organizations that are already well developed can achieve even better results.

Procurement’s various organizational models and their weaknesses

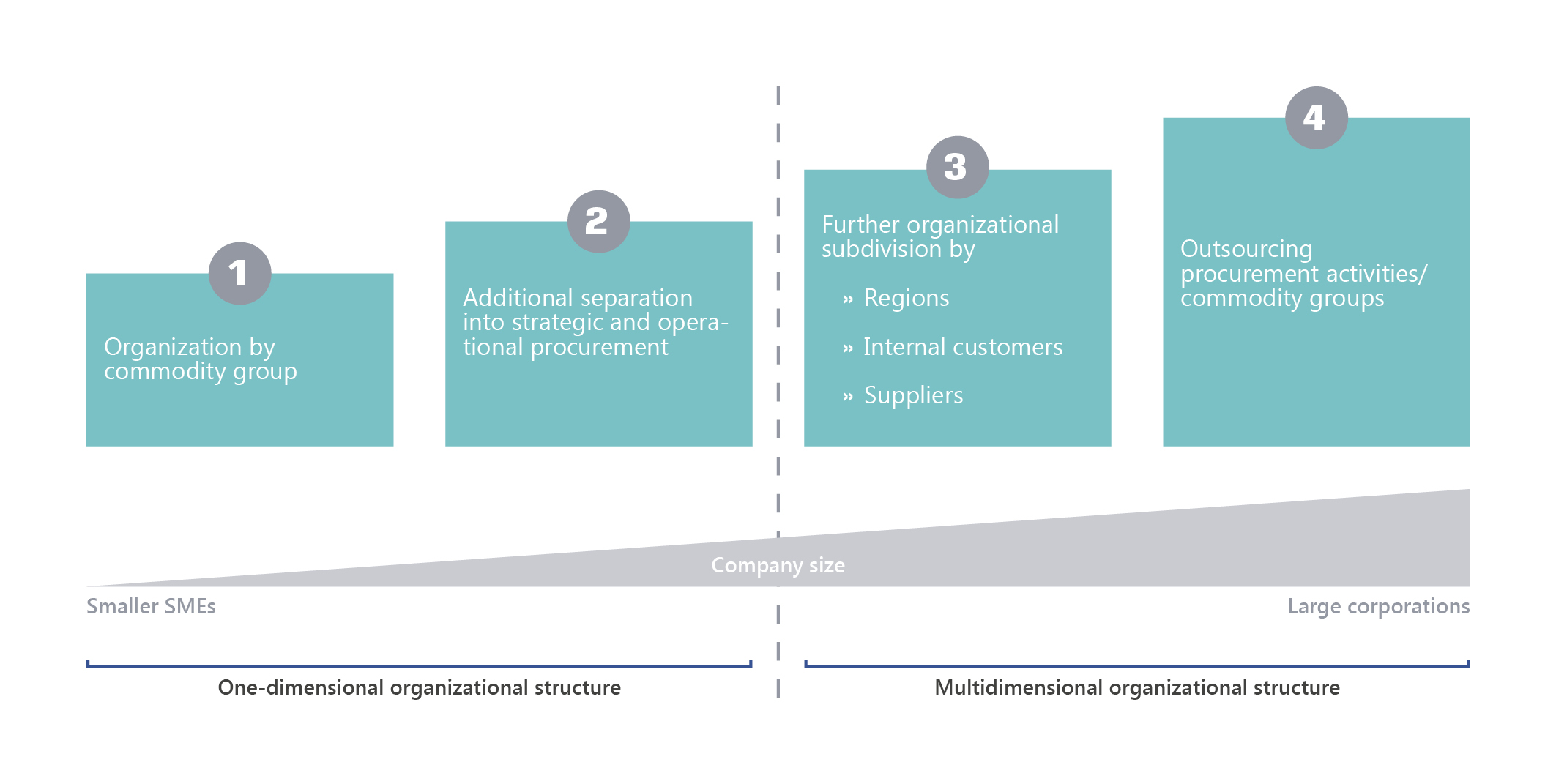

A procurement organization’s typical development cycle can be illustrated using a simplified four-phase model (see Figure 2):

- In phase 1, commodity groups are separated, as is commonly done by companies that have many of them

- The next step is categorizing tasks as either strategic or operational

- Larger businesses also subdivide into sourcing regions, internal customers, and suppliers

- Large corporations often decide to outsource procurement activities and commodity groups to specialized service providers, so as to achieve savings and process benefits

Manufacturing companies combine volumes and use standardization to achieve maximum effectiveness and efficiency in procurement. A centralized organization or a mixed model with strong centralized buying is the first step towards industrialized procurement.

This development has an effect on how the company’s various strategic buyers do their work and understand their own roles. They set strategic goals in accordance with overarching procurement goals and strategies, and “dummy-run” the strategic procurement process for the commodity groups for which they are responsible. They also establish the link to operational procurement and define the framework within which operational procurement can operate. The breadth of their responsibilities places particular demands on those involved in strategic procurement.

Buyers can find it difficult to manage such varied tasks. Many are only competent in certain aspects of the procurement process. One person may be able to perform complex evaluations, but will struggle to negotiate procurement terms effectively. These differences mean that most strategic buyers can’t do all of the things required of them with the same degree of success.

So how can companies get their procurement – including strategic procurement – performing at its best?

Industrializing procurement through its intelligent organization:

Businesses have to industrialize strategic procurement through standardization and specialization, so that strategic buyers’ job profiles are less diversified. A “smart procurement organization” is based on specialized roles with responsibilities that span different process stages and commodity groups.

These four roles are project management, assistance, method development/quality assurance, and information management (see Figure 1). A specialized organizational structure increases procurement’s competence and quality by developing specialists in different areas of responsibility. This produces significantly better work results.

The 4 Roles in a Smart Procurement Organization

Industrializing the strategic procurement process – the gentle approach

Although a smart procurement organization has many advantages, some companies are resistant to change. Employee organizations can be especially critical of changes to job profiles and the job losses caused by automation. This can make it much harder to transition to a procurement organization that is fully "smart". One solution for companies that are unable to implement the ideal “smart procurement organization” is to take a softer approach to industrializing the strategic procurement process, which employee organizations will usually support.

1. Identifying Operational Tasks at Every Stage of the Strategic Procurement Process:

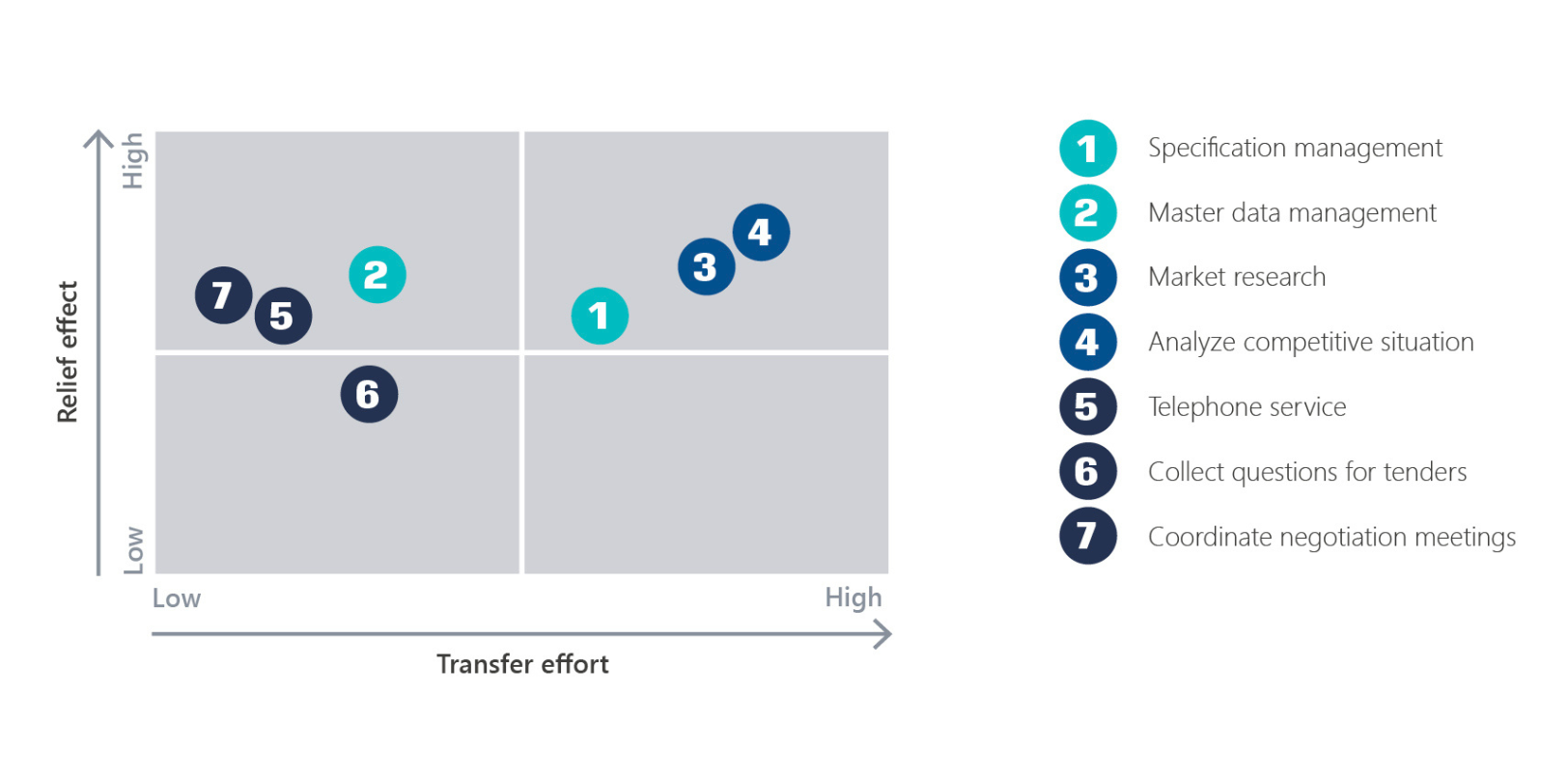

The first step towards reorganizing existing responsibilities is to identify the operational tasks that are embedded in the strategic procurement process (see Figure 3). Some tasks will be easier to separate off than others, depending on the level of operative procurement (see Figure 4). But all of them should be identified to begin with.

2. Separating Off Operational Tasks:

Operational tasks identified in strategic procurement should be prioritized according to the work required to transfer them and the anticipated relief from doing so (2x2 matrix, Figure 4). Tasks that require little work and provide high relief should be transferred first, taking into account any differences specific to commodity groups.

In an ideal “smart” procurement organization, procurement market analysis tasks should be handed over to a dedicated team of specialists. If the role of supply market analyst doesn’t exist, examine which tasks from this area can be taken over by operational procurement. In most cases, at least some procurement market research responsibilities (such as simple and clearly defined research and analysis tasks) can be transferred without difficulty.

3. Redistributing Operational Tasks:

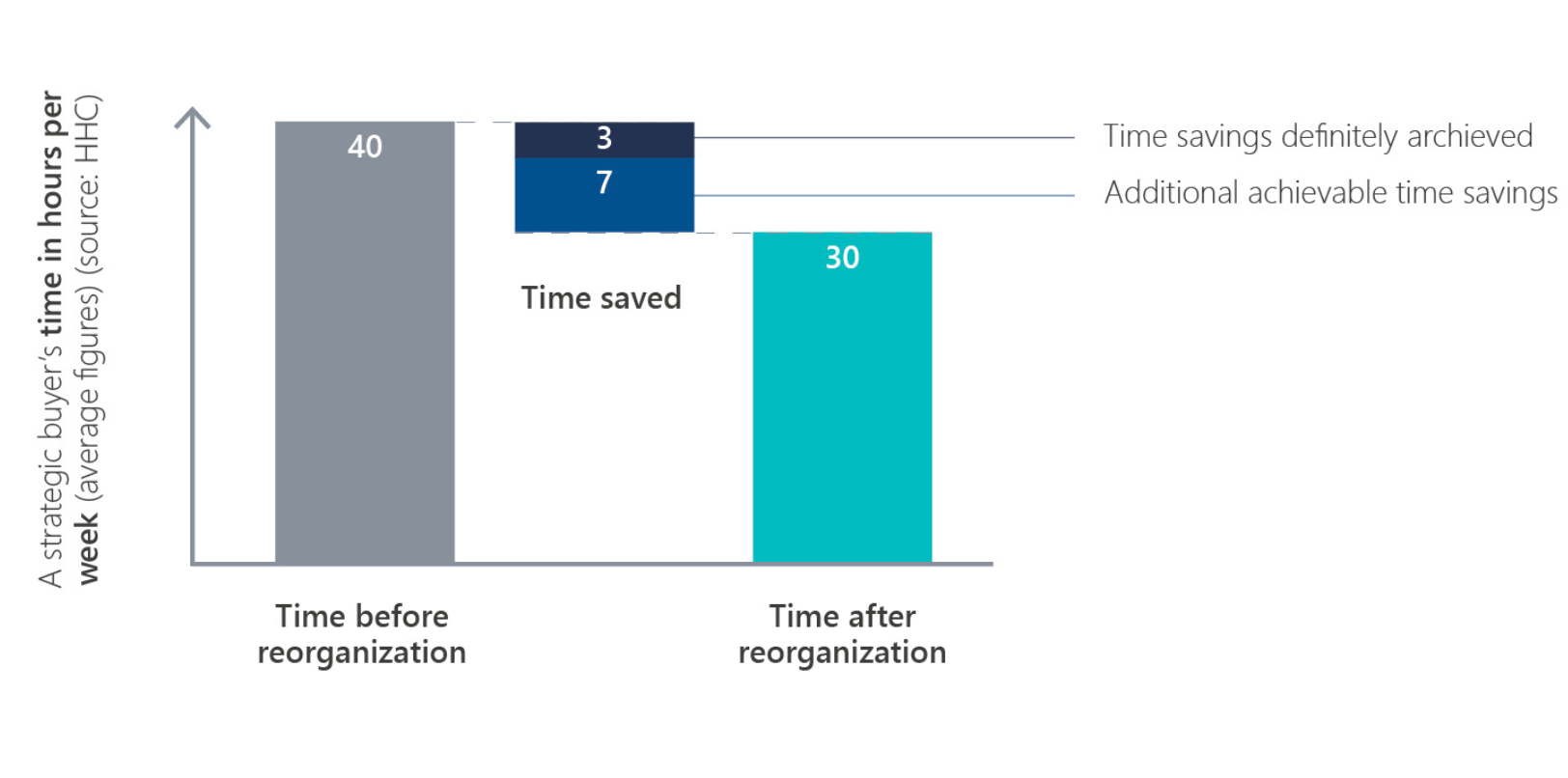

Tasks identified and separated off should be taken over by operational procurement to free up strategic procurement. This should be clearly communicated and integrated into daily work routines to achieve weekly time savings of up to 10 hours.

Up to a quarter of a strategic buyer’s weekly working time can be freed up this way, which, if they work for 40 weeks per year, means 50 extra days for strategic procurement tasks.

Learn more about the third step of our IDEa concept here:

HÖVELER HOLZMANN - a valantic company

Bahnstraße 16

40212 Düsseldorf

Germany

Phone: +49 (0) 211 - 56 38 75 - 0

Fax: +49 (0) 211 - 56 38 75 - 69

Email: info@hoeveler-holzmann.com